Different Solar Panel Types | Find the Right Solar Panel That You Need for Your Home

Solar panels not only reduce a financial burden on you by cutting down electricity bills but also help reduce environmental pollution by minimizing your carbon footprint. Invest in the best solar panel types to increase ROI.

Before we discuss different solar panel types, first, let us learn about the sun’s solar energy potential and its prospects. A research study conducted by photovoltaic industry experts revealed that the energy consumption of the whole world for one year was equal to the energy showered by the sun on Earth in less than a minute.

According to a scientific calculation, the sun generates more energy in 24 hours than the total electrical energy that the total population of Earth may use in 27 years. In this way, investing in solar energy is truly a sustainable and reliable source in addition to being very cost-effective and affordable.

To benefit from such promising solar energy prospects, we just need to understand and choose the right solar panel types for our solar projects based on the location where we live.

In this article, I will explain what solar panels mean, what are the different solar panel types, and how these types convert sunlight into electricity.

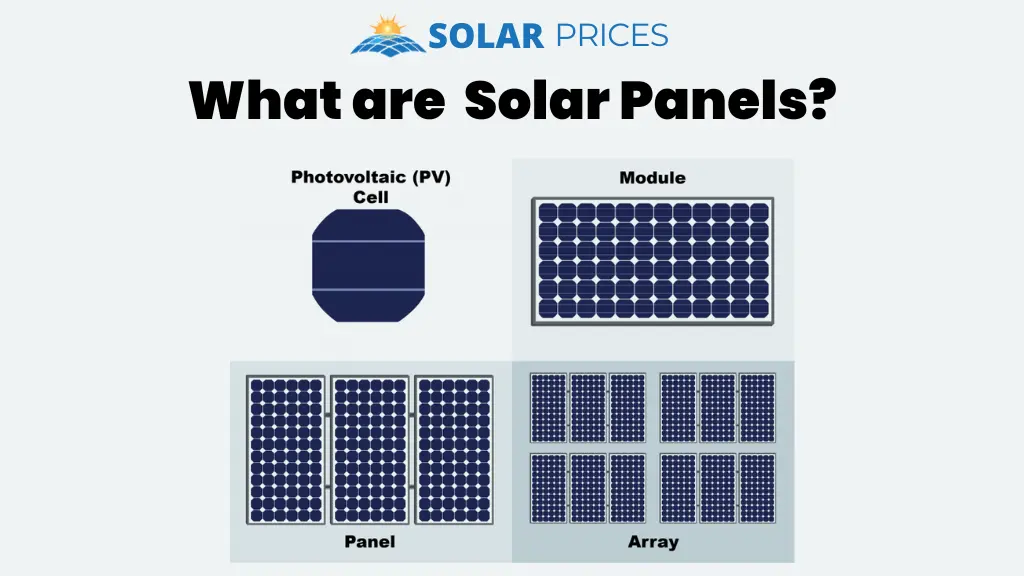

What are Solar Panels?

Solar panels consist of a large number of solar cells (photovoltaic cells or PV cells) linked together to produce an optimum net energy. In a typical solar panel, there could be 60, 72, 90, or 144 solar cells linked in series. Each solar cell is composed of silicon wafers doped with boron, and phosphorus.

Doping is fundamental for solar cell manufacturing. Doping is the process of intermixing pure silicon material with trivalent or pentavalent impurities to prepare the n-type and p-type materials needed for the production of solar cells.

Solar panels, also known as PV panels, are electronic devices that absorb sunlight and convert it directly into electricity. Solar panels work on the principle of the “photovoltaics (photovoltaic effect)”.

Learn today’s solar panel prices in Pakistan.

What is the Photovoltaic Effect?

When a solar panel is exposed to the sunshine, the atoms in the solar cell absorb the sunlight ( photons of energy from the sun) and become excited.

The excited atoms liberate electrons, known as free electrons, and an electron-hole pair is generated that creates electric potential. This is a photovoltaic effect, first observed and reported by Edmund Becquerel in 1839.

An electric potential is an energy with which electrons move from one place to another and constitute electricity. This is how solar panels produce electricity from the sunlight to power electrical appliances in our homes.

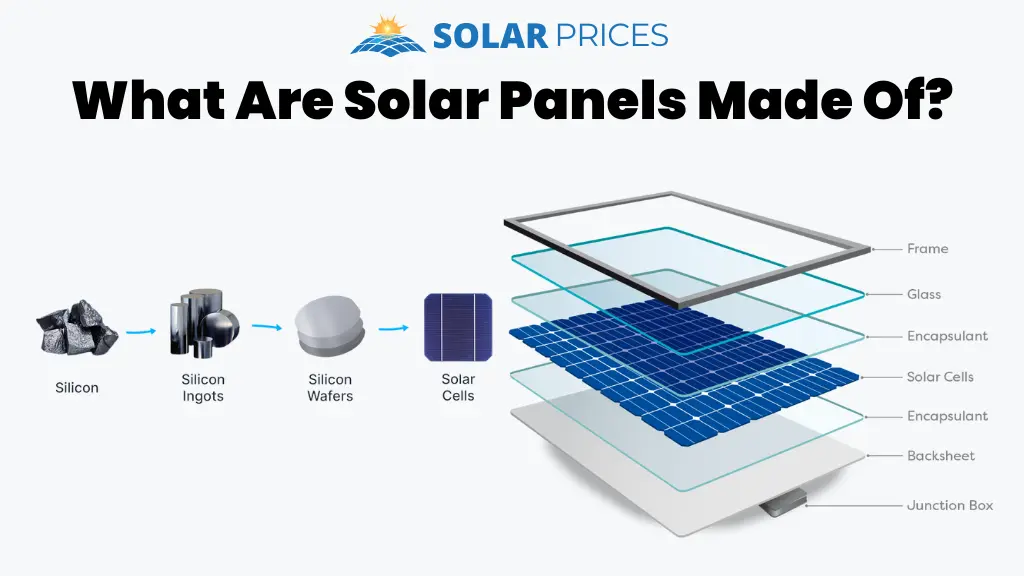

What are Solar Panels and Solar Cells made out of?

The most widely used solar cells are made of silicon, the second most abundant element on Earth, extracted from the sand. There are some other raw materials used including cadmium telluride, copper indium gallium (di)selenide, and thin-film amorphous silicon to manufacture solar cells.

A finalized and finished solar panel seems very simple and smooth, but many critical things go into assembling a solar panel. Broadly speaking a solar panel is made out of the following 6 major components:

- Aluminum Frame

- Tempered Glass

- Plastic Encapsulant-EVA

- Photovoltaic Solar Cells

- Back Sheet of Plastic

- Junction Box at the Back

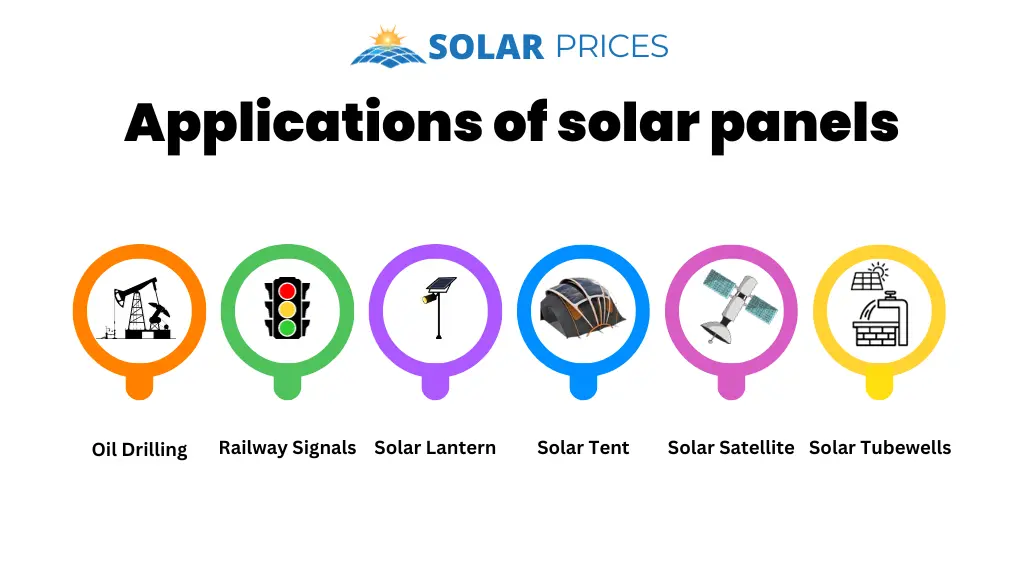

Various Applications of Solar Panels

Solar cell technology has revolutionized the world with its tremendous global potential for electricity generation. Other than residential, industrial, and commercial applications, solar panels are utilized for several other electrical usage. Check out the list below:

- Offshore Oil Drilling

- PV Powered Railway Signals

- PV Powered Pumps

- PV Powered Solar Lantern

- Pv Tent(Power Pack)

- PV Integrated Buildings

- Telecommunication Tower

- PV Refrigerator

- PV Satellite Power

- Remote Sensing

- Remote Power Systems

- SpaceCraft PV Integration

- PV Driven Water Tubewells

- PV Powered Gadgets i.e Watches, Toys

How to Categorize Different Solar Panel Types

There are thousands of solar panel manufacturing companies working across the world. They use different techniques and technologies in manufacturing solar panels. Their sole aim is to enhance the power conversion efficiency of photovoltaic panels (PV Cells).

So, there are different solar panel types available in the market. Each type serves differently up to a small extent. The fundamental purpose of each panel type is to efficiently convert sunlight into electricity whether it is used on Earth or in space-related applications.

But, be clear that your location is an important factor in deciding which type of solar panels would work in the best possible way for you. We can classify different types of solar panels for the number of layers on the solar panel or by generation.

In the following section, I will explain each type of solar panel with different parameters of significance.

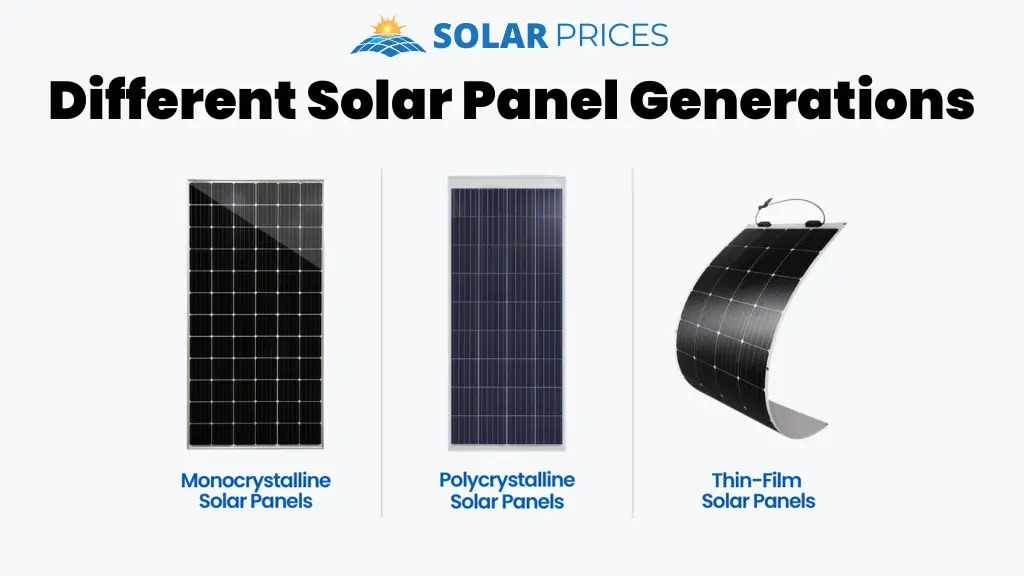

Solar panel types by generation?

There are three primary solar panel types based on the solar cell generation. These three types are currently available in the market on a commercial scale. We name each solar panel after the name of solar cell generation. Let us learn about different generations of solar cells below.

1st Generation Solar Panels

1st generation solar panels are made of monocrystalline(single crystal) or multi-crystalline (polycrystalline) silicon or gallium arsenide (GaAs) based solar cells. They are currently the most widely adopted solar panels due to better performance and solar energy conversion rate.

2nd Generation Solar Panels

2nd generation solar panels are based on thin-film solar cells. In the case of the first generation, silicon layers in large ( say hundreds of microns) sizes were used for cell manufacturing and it was too costly. So, to resolve the cost issue and minimize material usage, the second generation of solar cells was introduced.

In this generation, to optimize material usage the maximum film thickness of the solar cell was cut down to just a few nanometers to tens of microns. These solar panels were used for residential solar systems, smaller solar projects, and solar power stations.

2nd generation solar cells are also known as thin-film photovoltaic cells. The semiconducting wafers were developed from “microcrystalline silicon (µc-Si) and amorphous silicon (a-Si), copper indium gallium selenide (CIGS) and cadmium telluride/cadmium sulfide (CdTe/CdS) photovoltaic cells”.

3rd Generation Solar Panels

Solar cells of this generation are made out of various thin films. Most of these thin film technologies are still in experimentation and are not as efficient as the others.

3rd-generation solar cells are organic dye (solution) based solar cells. The research or development on this generation of solar cells is still ongoing. The solar cells use organic materials to generate electricity by absorbing sunlight.

Different types of third-generation solar cells are dye-sensitized solar cells (DSSCs), organic photovoltaics (OPVs), perovskite solar cells, copper zinc tin sulfide (CZTS), tandem solar cells, and quantum dot-based solar cells.

The main focus of this generation is to achieve higher solar power-conversion ratings at a very affordable cost., a stacked form of different materials utilizing a maximum solar spectrum to achieve high power conversion efficiency.

Solar panel types by structure (cell technology)

Solar panels (or solar modules) are assemblies of solar cells placed into a supporting aluminum frame or structure and other shielding glass layers to protect it from damage.

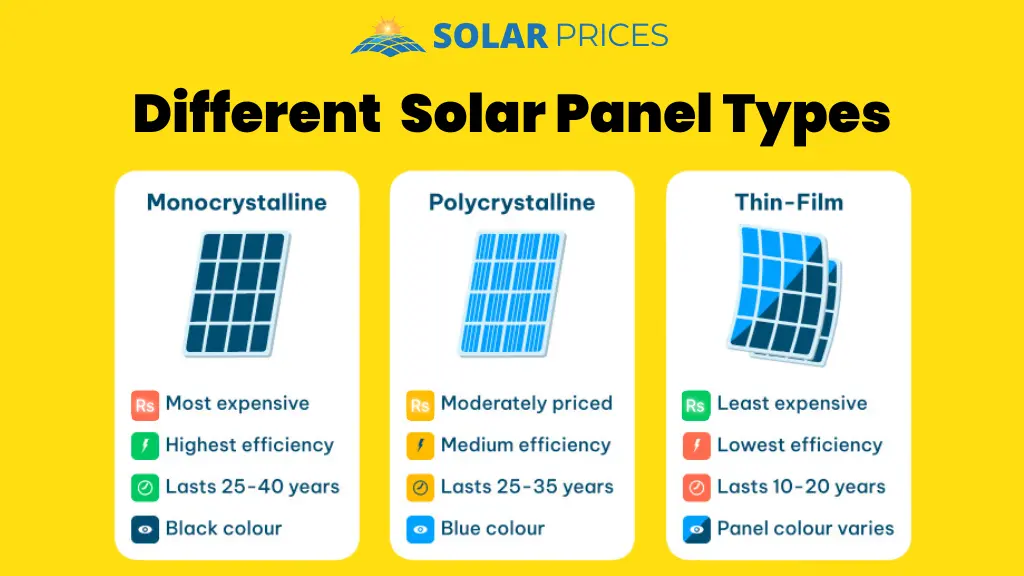

Silicon wafers are the key component in solar cell manufacturing. The dominating solar panels in the market are silicon-based. On the whole, solar panels are divided into three primary types namely monocrystalline, polycrystalline, and thin-film solar panels. Let’s nail down each of them in the following:

Monocrystalline solar panels

Monocrystalline solar panels ( also named single-crystal panels) are made out of pure silicon single crystal. Using a single crystal for mono-crystalline cells makes these panels the most space-efficient and has a longer life span than all other panel types.

First, a large cylindrical ingot of silicon is made and then thin layers are sliced to create wafer cells. This manufacturing process comparatively uses more resources. So, this type of solar panel is a little costly.

Monocrystalline solar panels offer slightly higher efficiencies. These panels are available in standardized sizes of 60, 72, 96, and 144-cell counts.

Polycrystalline solar panels

Polycrystalline(also referred to as multi-crystalline) solar panels are made out of multiple silicon crystals as the name implies. These solar panels can have a flaky look distinction over the monocrystalline panels.

Different silicon fragments are used to develop silicon square ingots in multiple molds. This process potentially uses fewer resources intensive to large-scale cell production. In this way, polycrystalline solar panels are much more affordable.

The polycrystalline silicon solar panels come in standardized sizes of 60, 72, 96, and 144-cell counts. If we consider the efficiency and lifespan of solar panels, poly panels were slightly less efficient in terms of space and light energy-conversion performance.

But this was in the early days, now, the process of manufacturing polycrystalline cells has much improved. These days, the efficiency and performance of poly panels are comparable to monocrystalline panels.

Thin-film solar panels

Thin-film solar panels are highly flexible, lightweight, and easy to install. These are made by the deposition of 350 times thinner layers of photovoltaic materials as compared to the traditional crystalline solar panels.

Thin film solar panels can be turned into different shapes, like shingles or roof tiles easily. They are less labor-intensive and cheap as well. Unlike other panel types, these panels do not need a sturdy frame backing to protect from accidental and environmental damage.

These panels are available in different sizes to suit your specific needs. However, thin-film solar panels have a much lesser efficiency and a higher rate of degradation.

The semiconducting materials used for manufacturing these solar cells include Cadmium telluride (CdTe), Amorphous silicon (a-Si), and Copper indium gallium selenide (CIGS).

These materials have some cons like toxicity and less resistance to degradation. That’s why thin film solar panels have a very low commercial profile as compared to the other panel types in the solar industry.

How different solar panel types look like?

There are three main solar panel types traditionally adopted by the solar panel manufacturers. Out of these three, monocrystalline or polycrystalline panels are installed on a large scale in conventional surroundings across the globe. Each type has its pros and cons as well as a different look and feel.

The difference in solar cell manufacturing materials and techniques gives them a distinct appearance. In the following, I will differentiate solar panel types by their appearance. That knowledge may help you cross-verify the panel when you buy it for your solar project.

Monocrystalline solar panels: dark-colored or blackish appearance

The solar panels made of pure monocrystalline silicon look black or dark-colored. It’s easy to recognize these panels because of a uniform dark look and a bit of rounded corners or edges.

If in your surroundings you see black or dark-colored solar panels, more chances are to be a mono panel. Monocrystalline cells give a black appearance, first, because of the purest silicon crystals used and secondly, more of the light interacting with the panel is being absorbed. The black, silver or white metal frames also enhance the look of the panels further.

Polycrystalline solar panels: blue or flaky look

Polycrystalline solar cells are made by melting raw silicon fragments. So, poly solar panels look a bit flaky or speckled with a bluish shade. A little color-conscious or a person with normal eye vision can quickly recognize the polycrystalline solar panels.

These panels also tend to have a squared appearance with blue hues. This is because of different trapping and de-trapping or irregular light reflections from the multiple silicon fragments in the wafer cells.

Thin-film solar panels: colorful profile

Thin-film solar panels come in both black and blue colors. It actually depends on the composition of layers. They can also have other colorful profiles based on the deposited materials and chemicals.

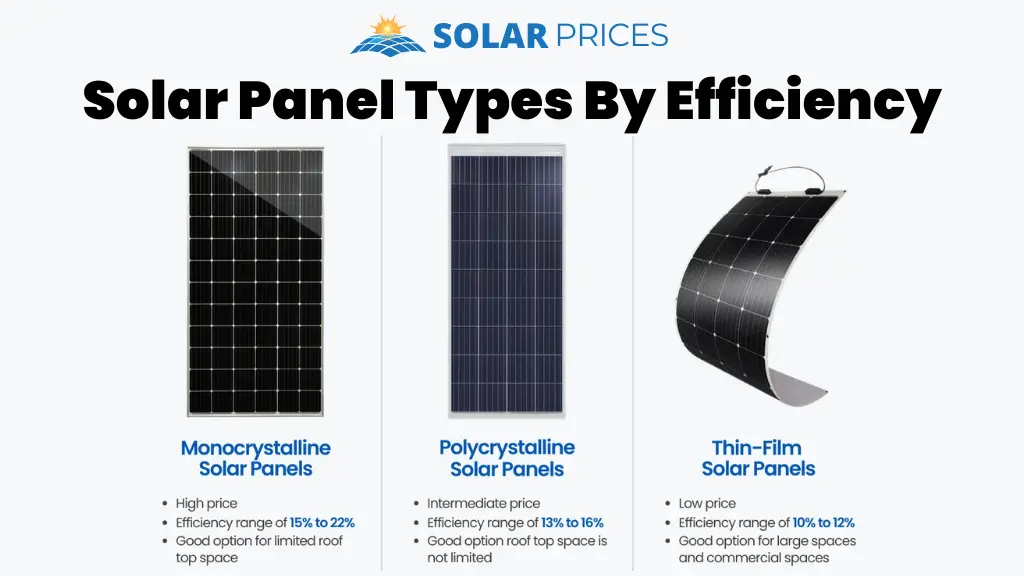

Solar panel types by efficiency

Monocrystalline Solar Panels: Most efficient

This type of solar panel is typically the most efficient in conventional silicon-based solar panels to date. These are also the most stable and have characteristic properties of the purest silicon that make a panel much more heat-resistant and long-lasting. The highest efficiency of monocrystalline solar panels lies in the range of 17% to 23%.

Polycrystalline Solar Panels: Mid-range efficiency

Polycrystalline solar panels are made with a bit less pure silicon wafer cells as compared to monocrystalline cells. They also have lower heat tolerance and their performance falls in high-temperature surroundings and environments. So, their efficiency rating falls between 15% to 20%.

Thin-Film Solar Panels: The lowest efficiency

Depending on the type of PV material used in the cells, thin-film solar panels’ efficiency varies, but generally speaking, it ranges from 6% to 13%, with amorphous silicon having the lowest rating.

Compared to other types, thin-film panels use less semiconductor material, which results in a lower efficiency and less weight. They also have a shorter lifespan than mono and polycrystalline panels due to their lightweight construction, which causes them to deteriorate more quickly.