LONGi Solar FAQs: Everything you need to know about LONGi Company

LONGi Solar is a leading solar technology company specializing in the research, development, and manufacturing of high-efficiency solar modules and related products. They specialize in creating high-efficiency solar modules, which are essential components of solar power systems used for generating clean and sustainable electricity.

With a commitment to innovation and sustainability, LONGi Solar plays a significant role in advancing the adoption of solar energy worldwide, contributing to a greener and more sustainable future. The bottom line- LONGi Solar is a globally recognized company that focuses on the design, development, and production of cutting-edge solar energy solutions.

You may also want to read about Solar panel maintenance.

Other quick links for your convenience.

Difference between Single-glass and Double-glass Solar Panels

What are P-type and N-type Solar Panels?

LONGi Solar FAQs: Everything is Covered in FAQs That You May Need to Know About LONGi Products

Why did LONGi choose a cell size of 182mm for Hi-MO 5 and Hi-MO N?

LONGi investigated different boundary conditions associated with module manufacturing and system application, including production feasibility, module dependability, application compatibility, transportation, and manual installation, before determining the size of 182 silicon wafers and modules.

For example, during shipment, the 182 modules can maximize the use of shipping containers while lowering costs. The load reliability of the module is still secure at 182 modules, and increasing its size may introduce various reliability issues.

Why do LONGi’s Hi-MO N modules choose TOPCon technology?

LONGi has made significant R&D investments, and the team is constantly monitoring and studying new cell and module technologies. LONGi has made advances and upgrades to TOPCon, naming it HPC technology.

As a result, modules based on this technology begin to provide evident consumer value in specific application scenarios, and LONGi will market this type of product at the appropriate moment.

What is the current status of the LONGi BRIGHT products?

To be used in structures with lower light permeability requirements to provide an attractive building look and PV generation.

What is the investment return rate for LONGi BRIGHT products?

The payback period varies based on the roofing condition and installation location, however, it typically ranges between 8 and 10 years.

What is the distinction between the LONGi ROOF BIPV system and regular roof distributed PV?

The LONGi ROOF BIPV system incorporates the PV power generation system and is a high-quality metal roofing maintenance system with a complete structure that meets architectural design requirements, including complete purlins, inner plates, insulation cotton, outer plates, and a layer for PV power generation are all examples of roofing building details.

Traditional roof-distributed PV refers to a PV system installed on the roof.

What is the construction process for the LONGi ROOF BIPV system?

The roof construction is fundamentally the same as that of conventional color steel tile roofs, and the colored steel tile must be pressed on-site and automatically locked by an automatic edge locking machine.

To eliminate manual participation, LONGi automatic installation equipment will be employed for automatic gluing, as well as pre-punching and automatic fastening on a wide scale. LONGi has also developed a faultless SOP system to provide uniform construction assistance.

How does the LONGi ROOF BIPV system’s roof panel and PV power generation layer connect?

or

How do you ensure the bonding quality and durability?

The silicone structural sealant connects the roof panel and the PV power generation layer. Silicone structural sealant is a high-modulus sealer that is easy to apply and can bear structural loads. It is very resistant to UV aging, as well as extreme temperatures and humidity.

Because of its excellent mechanical properties, which make the silicone structural sealant has good stability in the working environment from -50°C to 180°C and remains elastic without embrittlement, cracking, or tearing. It is widely used in structural engineering and assembly, especially in the structural assembly and hollow glass of high-rise building curtain walls, large-size glass panel curtain walls, and complex structure buildings.

What essential values do LONGi BRIGHT products offer to customers?

Apart from providing a decorative purpose to buildings, they also power them, lowering their energy use.

What control procedures does LONGi put in place to ensure module product quality?

LONGi’s three-dimensional capacity layout ensures the traceability of each module manufacturing link, while the highly automated production line, in conjunction with the base quality, headquarters quality, and marketing-end manufacturing supervision quality, ensures module quality.

It picks module materials based on its high standards and requires novel materials to undergo longer qualification and reliability tests before being included. As a result, third-party laboratories such as RETC and PVEL have given LONGi modules high marks for quality.

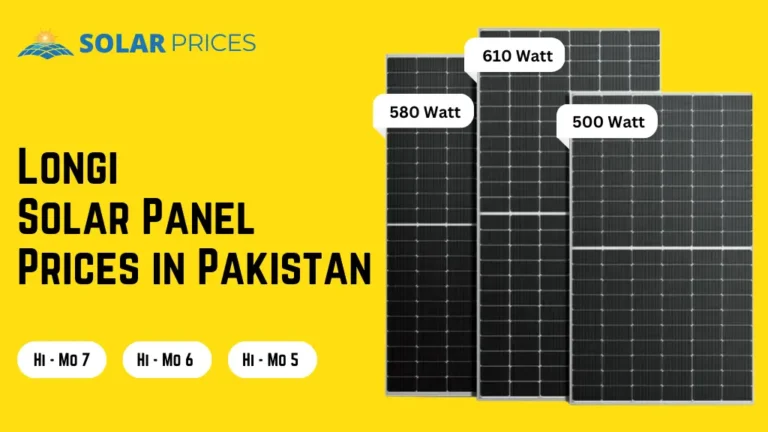

What are the classification and application situations for the three LONGi module product series that LONGi presently holds?

Module products include Hi-MO 4, Hi-MO 5, and Hi-MO N. Hi-MO 4m is a mono-facial product from the Hi-MO 4 series that is mostly utilized on industrial, commercial, and residential roofs. In contrast, Hi-MO 4 bifacial modules are primarily used in ground power plants. Hi-MO 5 is mostly used in big ground power plants.

Hi-MO N is also appropriate for large ground power plants, particularly in places with high albedo, temperatures, and BOS costs. The Hi-MO N module can dramatically lower LCOE.

What are the application situations for LONGi BRIGHT products?

Industrial roofs that prioritize attractiveness and building facades that are less concerned with light permeability

What application conditions are suitable for the LONGi ROOF BIPV system?

The LONGi ROOF BIPV metal roofing system is appropriate for the steel structure system of lightweight buildings with portal steel frames; it may be used for both new steel structure building roofs and refurbished steel structure building roofs.

What are the advantages of LONGI Bifacial Modules?

LONGi led the way in conducting empirical tests for power plants with local and foreign organizations and clients, as well as studying the power-generating mechanism of bifacial modules in depth. LONGi’s bifacial modules are likewise far ahead of the industry, with cumulative shipments exceeding 20GW, providing clients with reference data and technical assistance.

What are the advantages of using Hi-MO N modules?

The Hi-MO N modules offer the following three advantages. LONGi’s N-type HPC cell technology enables Hi-MO N modules to achieve over 22% efficiency, potentially lowering power station construction and maintenance costs.

Hi-MO N exhibits improved bifacially, power temperature coefficient, module operating temperature, anti-light induced degradation performance, and power generation under low light. Compared to P-type bifacial modules, it has obvious power generation gain.

Intelligent welding with no damage or cracks in the battery manufacturing process, as well as rapid PID recovery, ensures high dependability, with a linear attenuation of no more than 0.4% annually.

What are the advantages of using Hi-MO 5 in-ground power plants?

Hi-MO 5 has high power and efficiency, making it more cost-effective in BOS; 2. Hi-MO 5 can increase the power of a single string, as well as significantly increase the DC/AC ratio when using string inverters, which can reduce the cost of electrical equipment and thus the LCOE; 3. Hi-MO 5 can reduce module logistics costs by maximizing container space utilization.

How do you run and maintain LONGi PARK?

The mobile app allows you to monitor its working status and set timely alarms. There is no requirement for regular duty shifts. It requires little O&M work other than cleaning because the equipment and materials utilized are from first-quality Chinese brands with a very low failure rate.

How do you select between monofacial and bifacial modules?

Based on the current pricing difference between monofacial and bifacial modules, when the back side of the module is not blocked, the light received by the back side of the bifacial module can greatly increase energy production.

Furthermore, the glass-glass encapsulation structure of the bifacial module is more resistant to environmental erosion caused by water vapor, salt fog, and other factors. Monofacial modules are more suited for tiling installations in mountainous areas and scattered applications.

How long do LONGi BRIGHT products last?

Power attenuation of at least 85% over 30 years.

How does the LONGi ROOF BIPV system maintain a steady high energy yield for 25 years?

The use of a high-efficiency monocrystalline PERC cell of M6 gallium-doped silicon wafer, as well as the adoption of more stable double-glazed module packaging, assures that the modules’ 30-year power attenuation does not exceed 15%. 2. The innovative cooling air duct design reduces the energy yield loss caused by BIPV cooling.

How does LONGi ensure the supply of manufacturing capacity?

LONGi boasts the industry’s greatest module production capacity of 50GW, and the integrated capacity arrangement ensures module supply is guaranteed. Furthermore, the global capacity plan allows for the global distribution of modules via land, rail, and sea transportation. Customers all across the world have acknowledged LONGi’s supply of modules.